Hydraulic Tube Benders-The Muscle Behind Metal Shaping

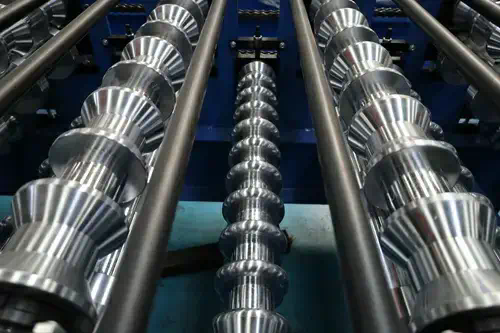

As a metal worker, you know that the ability to bend tubes and pipes accurately and consistently is essential for your craft. That’s where hydraulic tube benders come in. These powerful machines are the muscle behind metal shaping, allowing you to create smooth curves and precise angles in a variety of materials.

Hydraulic tube benders are used in a range of industries, including automotive, aerospace, and construction. They are commonly used to create parts for vehicles, such as exhaust systems and roll cages, as well as in building construction for handrails and support structures. In the aerospace industry, hydraulic tube benders are used to shape metal tubing for aircraft frames and engines.

One of the key benefits of hydraulic tube benders is their ability to create consistent bends. This is important when creating parts that need to fit together precisely, as even small variations in the shape of a bend can cause problems down the line. Hydraulic tube benders are also capable of bending thicker materials than manual tube benders, making them a better choice for heavy-duty applications.

When choosing a hydraulic tube bender, there are a few key factors to consider. The first is the bending capacity of the machine, which will determine the maximum size and thickness of tubing it can handle. You’ll also want to consider the bend radius, or the minimum size of the curve the machine can create. Other factors to consider include the speed of the machine, the type of control system it uses, and any additional features such as automatic mandrel extraction.

If you’re in the market for a hydraulic tube bender, there are several popular models to choose from. One of the most highly rated machines is the Baileigh RDB-250, which has a maximum capacity of 2-1/2″ tubing and can create bends up to 180 degrees. Another popular option is the Pro-Tools MB-105HD, which is capable of bending up to 1-3/4″ tubing and has a bend radius as small as 2.5″.

When using a hydraulic tube bender, it’s important to follow proper safety procedures. Always wear appropriate personal protective equipment, including safety glasses and gloves, and make sure you are familiar with the machine’s controls and operation before use. You should also be aware of the risks involved in bending metal tubing, such as the possibility of pipe bender for sale kinking or crushing the material.

In conclusion, if you’re a metal worker, investing in a hydraulic tube bender can greatly improve your ability to create consistent, precise bends in a variety of materials. When choosing a machine, be sure to consider factors such as bending capacity, bend radius, and speed, and always follow proper safety practices when using the machine. With the right hydraulic tube bender, you’ll be able to take your metal shaping skills to the next level.