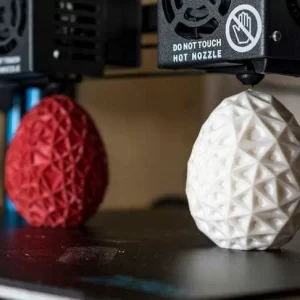

LCD 3D printing (also known as MSLA or Masked Stereolithography) is a relatively new technology, designed as an affordable alternative to DLP and stereolithography. It is similar to DLP in that an entire layer of resin can be cured at once. However, unlike DLP, LCD uses an array of ultraviolet LEDs as a light source. It also uses an LCD to selectively mask the UV light to ensure that only selected areas of the resin are cured in the layer. A higher LCD density means that the mask has more available pixels and can thus create sharper images and higher-resolution parts.

It is important to distinguish between LCD printers with mono-LCD and color LCD screens. Mono-LCD screens last much longer and print much faster than their color counterparts. This is because monochrome LCD screens allow more light through and feature better thermal resistance. The overall result is a faster resin curing rate and a longer lifetime than traditional color screens. The mono-LCD screen was specifically designed to address some shortcomings of regular color LCDs and takes LCD 3D printing to a new level.

LCD printers are geared towards mass manufacturing and the accurate printing of larger components. DLP, on the other hand, is more precise for small-scale details. LCD printers are also less expensive than DLP printers with comparable specs.

What Are the Advantages of LCD Compared to DLP?

LCDs have the following advantages over their DLP counterparts:

- LCD tends to have better print quality than low-end DLP machines.

- LCD is a better option for large components that don’t have fine details.

What Are the Disadvantages of LCD Compared to DLP?

LCD has the following disadvantages compared to DLP:

- LCD printers have shorter lifespans than DLP ones. The LCD screens must be replaced more often than DLP DMDs. This increases the lifetime cost of LCD printers.

- LCD printing tends to be slower than DLP.

- LCD results are less precise than DLP, especially when comparing high-end versions of both systems.

.webp)