How does the particle size of CBN grinding wheel affect its use effect?

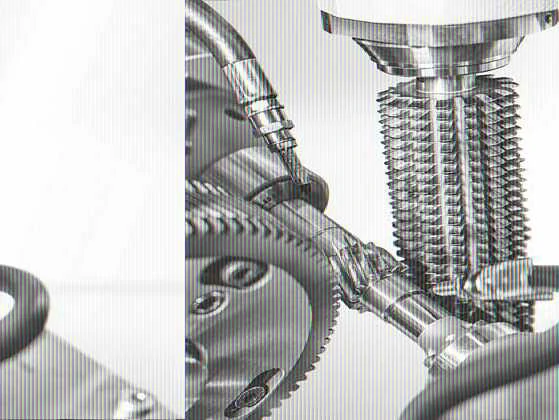

The particle size of a CBN (Cubic Boron Nitride) grinding wheel plays a crucial role in determining its use effect. The use effect refers to the performance and efficiency of the grinding wheel in various applications. In this article, we will explore the impact of particle size on the use effect of CBN grinding wheels.

Firstly, let’s understand what the particle size of a grinding wheel means. It refers to the size of the abrasive particles present on the surface of the wheel. The particle size is typically measured in terms of grit size, which represents the number of abrasive grains per inch of the grinding wheel. A smaller grit size indicates larger abrasive particles, while a larger grit size suggests smaller particles.

Now, let’s delve into how the particle size affects the use effect of CBN grinding wheels.

1. Surface finish: The particle size of the grinding wheel has a direct impact on the surface finish achieved after grinding. Smaller grit sizes produce finer surface finishes, whereas larger grit sizes result in relatively rougher finishes. For applications that demand high precision and smoothness, such as in the aerospace or medical industries, finer grit sizes are preferred.

2. Material removal rate: The particle size also influences the material removal rate during grinding operations. Coarser grit sizes tend to remove more material with each pass, leading to higher material removal rates. On the other hand, finer grit sizes remove less material but allow for more precise control over the grinding process. Therefore, the choice of particle size depends on the specific application requirements, considering the desired material removal rate and accuracy.

3. Grinding efficiency: The particle size affects the grinding efficiency of CBN wheels. In general, smaller grit sizes offer higher grinding efficiency due to their ability to create finer chip sizes during the grinding process. Finer chips are easier to evacuate from the grinding zone, reducing heat generation and improving overall efficiency. However, it is essential to strike a balance between grinding efficiency and tool life, as smaller particle sizes may lead to quicker wear of the CBN wheel.

4. Wheel wear: The particle size influences the rate of wheel wear during grinding. Finer grit sizes typically experience less wear and maintain their shape better compared to coarser grit sizes. This is because finer particles distribute the grinding forces more evenly, reducing the stress concentration on individual abrasive grains. Consequently, choosing an appropriate particle size can help prolong the lifespan of the CBN grinding wheel.

In conclusion, the particle size of a CBN grinding wheel has a significant impact on its use effect. The choice of particle size depends on the desired surface finish, material removal rate, grinding efficiency, and wheel wear. It is crucial to consider the specific requirements of the application to select the most suitable particle size. By optimizing the particle size, users can enhance the performance and effectiveness of CBN grinding wheels in various industries and applications.

.webp)