Form grinding refers to the grinding method that uses a shaped grinding wheel to move relatively along the workpiece, or the formed grinding wheel is directly fed forward to shape the workpiece.

■In-depth introduction:

Common grinding methods such as plane, inner and outer circle, centerless, etc., and forming grinding are rarely mentioned, but in fact this type of grinding is not inferior to the aforementioned processing methods, and is widely used in cutting tools, such as milling cutters, Reamers, broaches, lathe centers, or mold parts, such as linear slides, connector molds, tooth plates, etc., in today’s increasingly high precision requirements, the quality and efficiency requirements for forming and grinding are also increasing. Higher and higher.

■Application:

Common practical applications are as follows:

◆Broaches, milling cutters, and gear hobbing cutters, such as those with spirals or grooves, will trim the front edge of the grinding wheel into a convex shape similar to the tip of a pen, and then move the workpiece relatively axially, slowly To form the required size and depth, but in recent years, the most common use of disc-shaped grinding wheels is to form directly, and the accuracy and stability are higher.

The same is true for Molex connectors, which are used in high-precision applications such as electronic parts and mobile phone charging holes. The connectors are small in size and high in precision. Of course, high precision is required in making other molds, and the thickness of the grinding wheel needs to be formed to be very thin. , It may be dozens of thinness to grind to get the precise size. In the process of grooving and corner cleaning, it also tests the patience and skill of the technician.

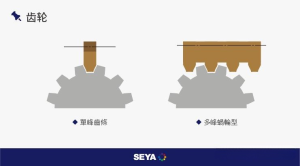

◆For the forming of gears, the gears are not only in the form of single-peak racks, but also the grinding wheels are formed into multi-peak worm gears, which are straight-forward for grinding. The difference between the two is that the contact area of the rack is small, the heat is less, and it is not affected by the length of the workpiece. It is easy to trim, but the disadvantage is that the efficiency is slow. Although the worm wheel type can quickly achieve molding, but the contact area is large and easy to generate heat, the effect is not easy to control, and trimming is also difficult.

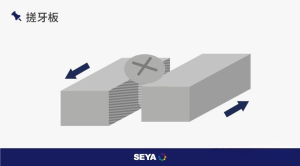

◆Die rubbing board, this type belongs to mold forming. Its function is mainly to form the external thread of the screw by moving the two tooth boards back and forth, so as to achieve the purpose of mass production. Molding generally locks many workpieces at once to improve production efficiency.

Compared with the forming of the outer circle, the forming result of the plane is easier to control. Some outer circle forming also requires special function grinding machines such as turret rotation, or oblique entry type, and the rigidity of the grinding machine and the strength of the grinding wheel for forming grinding. There are higher requirements. In the next article, I will mention the key points about the selection of forming grinding wheels, so that everyone can have a deeper understanding of forming grinding. Please look forward to it.

The above is the sharing of SEYA. If you have any questions about the selection and matching of grinding wheels and adjusting wheels, or grinding related technologies, please contact us for consultation!